Certainly I realize that this is a fairly low-cost monitoring system. Undeniably there are bigger and better ways to monitor exactly who is coming and going and at exactly what time. You could retina or fingerprint scan workers like 007 movies but at what cost? You could have card scanners but then look at the expense of installing that for one or two workers. What if they forget their card or lose it? Often the "home office" is far away and the logistics of getting a new card could take days. Or a substitute needs to go to the site who doesn't have a card? A simple low-cost employee monitoring device could be the solution.

Here is what I did.

I installed a simple door sensor that sends a count of how many seconds the door is open in 5 minute intervals for each time it is opened. That information is then sent to Grovestreams where I am doing some simple analysis with it that provides me with some excellent information.

Data #1. I get the first time of the day that the door was opened up. This is huge. If the employee is supposed to be at the site at 6am and they regularly arrive at 9am that is a problem.

The image above shows activity on a system that monitors a door at my office. Grovestreams allows for an easy way to determine the first and last timestamp of activity received for the day and shows it in a dashboard.

In addition I can take the last timestamp and subtract the first and get an estimate of the time the site was occupied for the day.

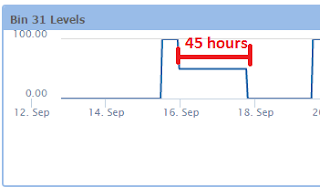

I also chart this for quick viewing (guess I haven't been to the office at all in the last few days):

Interesting alerts on this.

1. Send an alert to email or phone on the first arrival every day.

2. Send an alert to email or phone on activity outside of a time filtered period. Example send an alert for every activity outside the hours of 6am to 6pm.

3. Send an email at 12:01am if the duration of the previous day was less than 4 hours.

4. Same alert as #3 except for exclude weekends.

Expanded analysis:

Many sites have multiple barns. As part of the Multisense sensor gateway users could add door sensors to each barn entrance and managers could track how much time is spent in each of the barns on the site. Alerts for barn doors left open would be simple to include as part of any package as well.

Grovestreams and Multisense make prototyping IoT projects simple and low cost. This door sensor project took me hardly any time or money and now I think this could be used in barns all around to monitor employee time.