The Binlogic bin sensor provides some good data which can help feed mills know or predict when bins are empty and need a delivery scheduled. As this goes to press, we are still working on refining and improving the sensor but initial data is promising.

Installing even more sensors as well as predictive growth software can provide a lot of contextual information to effectively put a feed ordering program together for an entire feed mill system.

Some ways this can work:

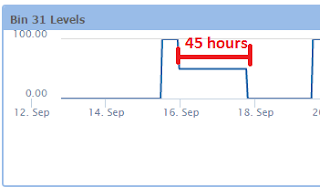

Utilize 1 high sensor and 1 low sensor. This is a great way to know a time frame from when a bin begins to be depleted until it is in the cone and more feed can be delivered. In the example below a trigger can be set for as soon as the sensor in the high goes from closed to open to put a feed order in for 45 hours later.

Furthermore, many sites use tandem bins. The example below shows that from the time that bin 31 starts going down to the time that bin 32 goes below cone is 96 hours. So, in this case a date range of between 45 and 96 hours from the time bin 31 first goes down could be pushed to the mill as a delivery window to ensure the site doesn't run out of feed.

Another strategy would be to look at these 2 time spans for the order window.

This strategy would call for a feed delivery from 66 hours to 119 hours from the time Bin 31 first starts to go down to ensure feed doesn't run out.

Even another strategy would be to send a notification to the feed mill as soon as a bin goes empty which triggers an order to drop and go out within X hours. If the feed mill has a queue of empty feed bins for which to deliver feed against it could make for an efficient system.

Yet another option would be to simply have a single high sensor and as soon as the feed went below the sensor an order was placed for X days from that moment. The days could be calculated based upon assumed consumption for animals of that size/age etc.

All of these strategies can be modeled in Grovestreams and passed into any feed mill software.

As with any of the sensors a full suite of intelligent alerting is available. Example: Receive notification when a bin goes below a certain level, feed is ordered but hasn't arrived, intake is faster/slower than the assumed order rate among many others.

Much work is still needed on using these bin sensors to accurately order feed. Initial results have shown promise. Combining bin sensors with many other sensors ensures even better data and automation at a livestock site.